OEM/ODM customized service for core accessories of medical equipment - precise adaptation, empowering global medical care

As a professional factory deeply engaged in the field of medical accessories manufacturing, we focus on providing customized development and production services for products such as medical cables, blood oxygen probes, electrocardiograph cables, and medical ultrasound probes for global customers. Relying on the technical strength of the entire chain and a strict quality control system, we help customers quickly seize the medical equipment market.

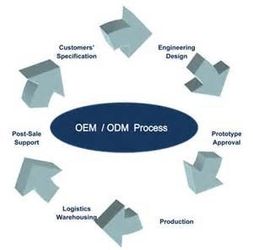

Features of OEM/ODM services

Adapt to global brands: support mainstream device interface protocols such as Philips, GE, and Mindray, provide customized designs such as cable length, connector specifications, and signal shielding to ensure seamless connection with monitors, electrocardiographs, and ultrasound equipment.

Multi-scenario applications: covering scenarios such as in-hospital monitoring, emergency transportation, and home medical care, supporting special performance requirements such as anti-interference, bending resistance, waterproofing, and antibacterial.

Biosafety and material innovation

Medical-grade materials: using materials such as TPU, silicone, and biocompatible plastics, and passing ISO 10993 biocompatibility test to meet the needs of disposable or reusable use.

Sterilization adaptation: Ultrasound probe supports high temperature and high pressure sterilization process, blood oxygen probe provides IP67 waterproof packaging, adapted to hospital infection management standards.

Full process technology empowerment

Mold development to mass production: Own mold workshop and automated injection molding production line to achieve rapid response from prototype design to mass delivery, shortening customer product launch cycle.

Signal optimization solution: Through EMC laboratory testing and multi-layer shielding process, high-fidelity transmission of ECG signals and blood oxygen data is guaranteed, with an error rate of ≤±1%.

Core product customization capabilities

Product type Customization dimension Technical highlights

Medical connection cable Wire length, interface type, shielding layer structure Multi-layer twisted shielding + tinned copper core, anti-interference performance increased by 40%.Blood oxygen probe Adult/child size, disposable/reusable design Photoelectric sensor + flexible finger sleeve, both comfort and accuracy.ECG machine lead wire Number of leads, electrode material, wire flexibility Silver/silver chloride electrode + silicone sheath, resistant to bending 100,000 times.

Medical ultrasound probe Frequency range, number of array elements, ergonomic design of the handle Piezoelectric ceramic chip + broadband matching layer, image resolution increased by 30%.

Quality assurance system

Complete certification: Passed ISO 13485 medical quality system, CE, FDA certification, some products meet YY/T 0287 standards.

Full inspection and control: Each batch of products undergoes more than 20 strict quality inspections such as signal stability test, aging test, impedance detection, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!